V belt is made of elastic material. V-belt manufacturers have designed straps to connect two or more shafts. Belts can be used as a source to transmit movement and thus energy efficiently. Belts are the cheapest tool for sharing power between shafts that may not be axially aligned. Power is transferred by a specially designed pulley. The requirements for the belt drive transmission are substantial, and this has resulted in many variations of the theme. They run smoothly or with little noise and control the motor and bearings against load changes. However, belt engineering improvements allow for V-belts to be used in a system that previously only allowed chains or gears.

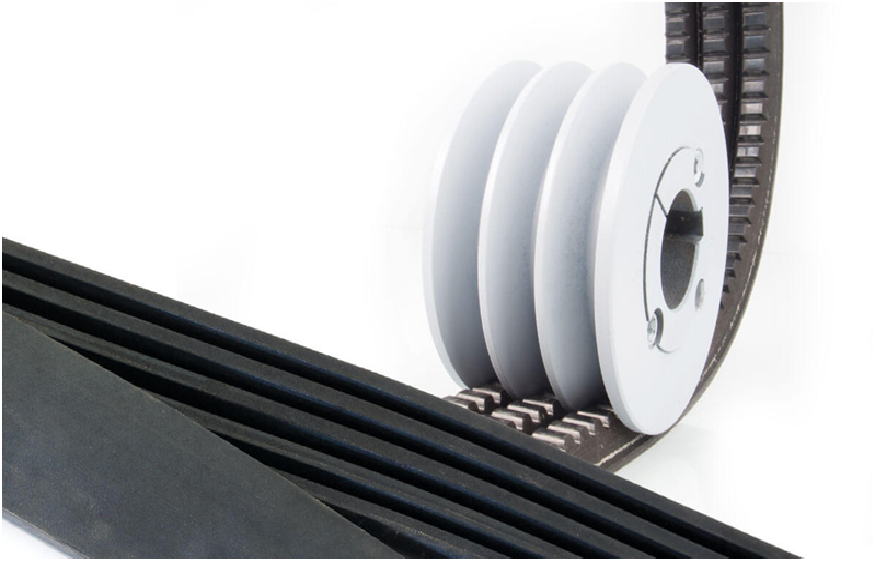

V-belt suppliers have primarily solved the problems of slip and alignment of V-belts by supplying the V-belt in the market. It is now the primary belt for energy consumption. These belts have a poleas trapezoidales cross-section. V-shaped belt tracks into the mating groove of the pulley. The transmission can be improved by increasing the wedge movement.

V-belt manufacturers have produced V-belts to outpace flatbeds with small center distance and reduction ratios. The preferred center distance is greater than the largest diameter of the pulley, but it is less than three times the sum of both pulleys. These belts need a larger pulley for cross-section thickness than flat v-shaped straps.

V-belt exporters claim multiple V-belt for transmission where power requirements are high. Two or more belts are joined side by side to form various V-belts. The belt can only be made of rubber or polymer. The fibers may be from textile materials such as cotton, nylon, and polyester. Sometimes the fibers may be incorporated into rubber or polymer for strength and reinforcement.

This is where crowned pulleys come in handy. They are fastened to ensure the belt is on the right track and not sideways. Crown pulleys, either tapered or poleas trapezoidales , consist of a drive pulley with a center diameter that is slightly longer than that at the ends. The difference in diameter causes the belt to correct itself by continually returning to its track as soon as it tends to swerve away.

When the endless belt does not fit the need, the coupling and the coupling can be used. Most models offer the same power and speed ratings, are infinite in size, and do not require special rollers to operate. The V-link is several polyester bonds compound together. These provide ease of installation and superior resistance compared to rubber bands, and the length can be adjusted by loosening and removing links when required.

There are many factors to consider when choosing a belt. Friction is one of the most critical factors. The belt is worn if the conflict is excessive. The belt tension dramatically affects the power transmission. V-Belt Exporters and Suppliers want belts that exhibit the least slip at high loads.